We help people repair plastic

Repairing Plastics with Two-Part Adhesives

Clean both sides of the plastic in the damaged area with 1000 Super Prep or 1001-4 EcoClean plastic cleaner. Fixture the front side with clamps or aluminum tape to hold the part together while the adhesive on the backside cures.

Sand the backside of the area to be repaired with 50 grit sand paper or coarser. A v-groove is not required unless you need to sand the backside flat for cosmetic reasons. Remove paint in the surrounding area with 80 grit in a DA. Heavy grooving of the plastic is desirable to maximize the mechanical strength of the bond. Blow dust free with clean, dry compressed air.

If the material is TEO, TPO or PP, apply 1060FP Filler Prep or 1050 Plastic Magic Adhesion Promoter. Brush or spray onto the sanded area and allow to flash off.

Choose a two-part adhesive system to match the hardness of the substrate according to the following table:

| Adhesive | Substrate |

|---|---|

| 2000 Flex Filler | flexible substrates, polyurethane, soft TPO |

| 2020 SMC Hardset Filler | rigid substrates, semi-rigid TPO, SMC, fiberglass |

| 2510 PlastiFix two-part | rigid substrates, Metton®, SMC, fiberglass, metals |

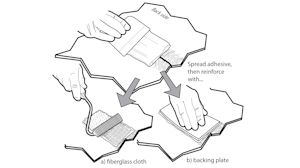

Select a reinforcing method for the backside of the part. For flat areas, it is often easiest to cut a backing plate out of scrap material. For contoured areas, use fiberglass cloth or drywall tape.

Prepare reinforcement by cutting 1 to 3 pieces of glass cloth to cover the damaged area about 2”-4” wide. If using a backing plate, make sure it extends at least 2” beyond damage in all directions. Rough grind the side of the backing plate that will be applied to the surface.

Mix the two-part adhesive according to package directions. Spread a generous amount on the backside with a body spreader. If using a backing plate, press the plate firmly into the adhesive, allowing a small amount of adhesive to squeeze out from the edges. If using fiberglass cloth, lay the cloth into the adhesive and wet the fibers using a 2042-R saturation roller. Apply more adhesive over the area and embed another layer of fiberglass cloth if desired.

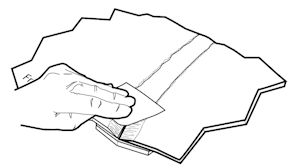

Once the adhesive on the backside is cured, peel the aluminum tape off the front and grind a v-groove about 1”-2” wide with a die grinder and/or a coarse sanding disc. Sandscratch the inside of the v-groove coarsely. Round off any sharp edges and feather the paint back with 80 grit in a DA.

If the material is TEO, TPO, or PP, apply adhesion promoter as was done on the backside.

Mix the two-part adhesive and apply into the v-groove with a body spreader. Slightly overfill the v-groove so that it can be sanded flush when finished.

When the adhesive on the front side is fully cured, sand with 80 grit in a DA sander, then progress to finer grits to finish.

plasticwelder polyvance nitrogen welder polyvance bumper repair plastic tank welding polyvance plastic welding kit

Products Suggestions